Polymer Processing Aids masterbatches

Our Polymer Processing AID grades are dedicated to Polyethylene, Polypropylene and TPV productions.

Film production

Polymer processing

Pipe & tube production

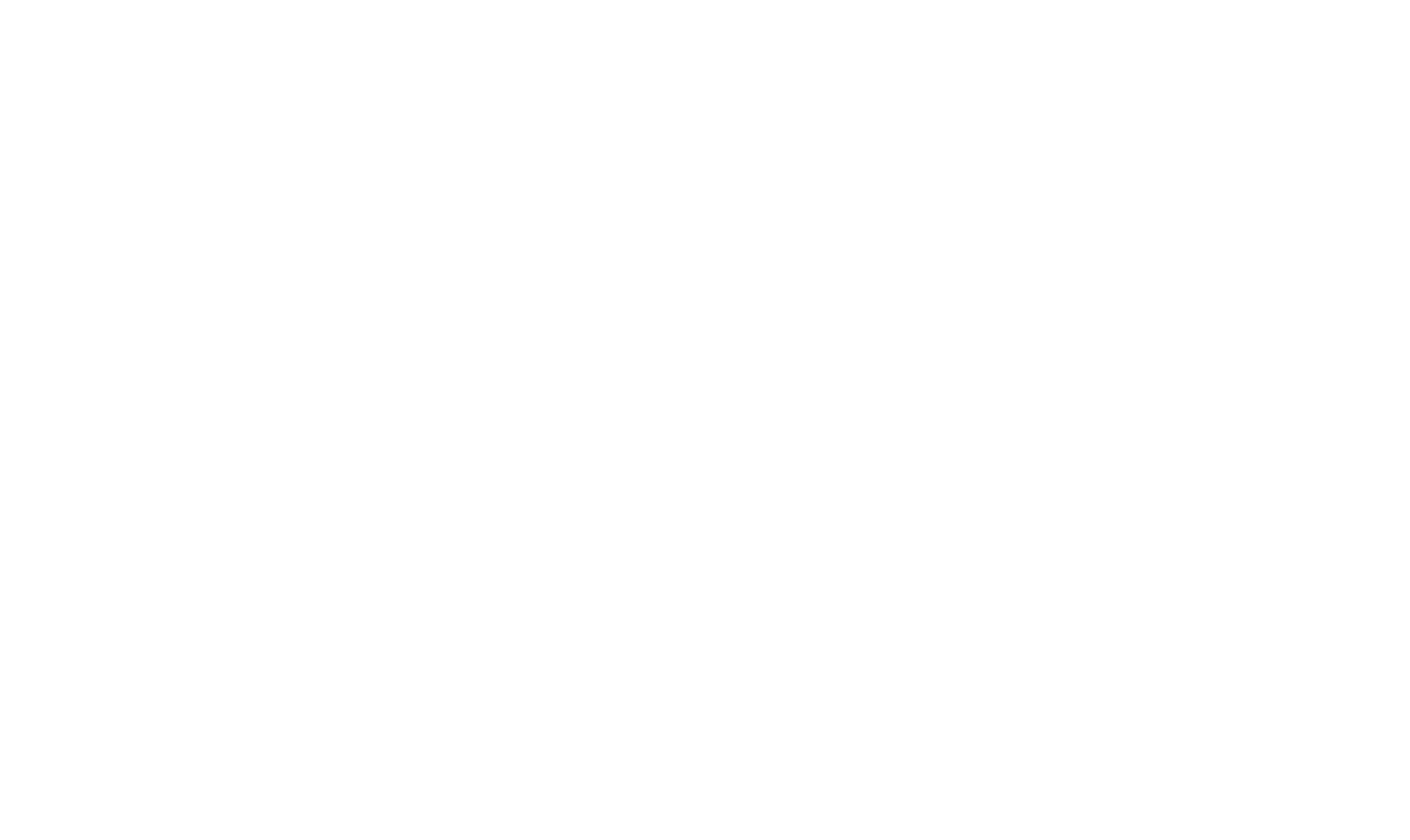

The mechanism

WHY ?

Issue #1:

Increasing throughput → friction between the metallic barrel walls and the resin material being processed

Consequences:

- Increase Pressure inside the barrel

- Resin being stressed and facing high shear

- Melt fracture, Hair angel Shark Skin

Issue #2:

- Critical phenomenon to avoid as long as possible during extrusion

cycle - Build up generated by high internal pressure and filler presence

wihtin the material can take several hours to form - When the agreggates become too massive, stripes and film

degradation happen

At the exit of the extruder, melt fracture, die build up and polymer degradation will cause gels and black spots presences on the surface of the converted polymer and when the deposit is too important, will force operators to stop the machine for cleaning operation.

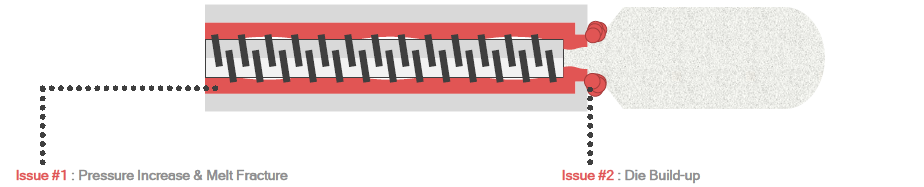

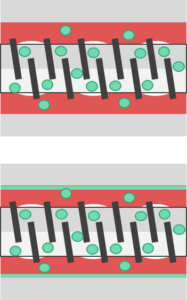

HOW ?

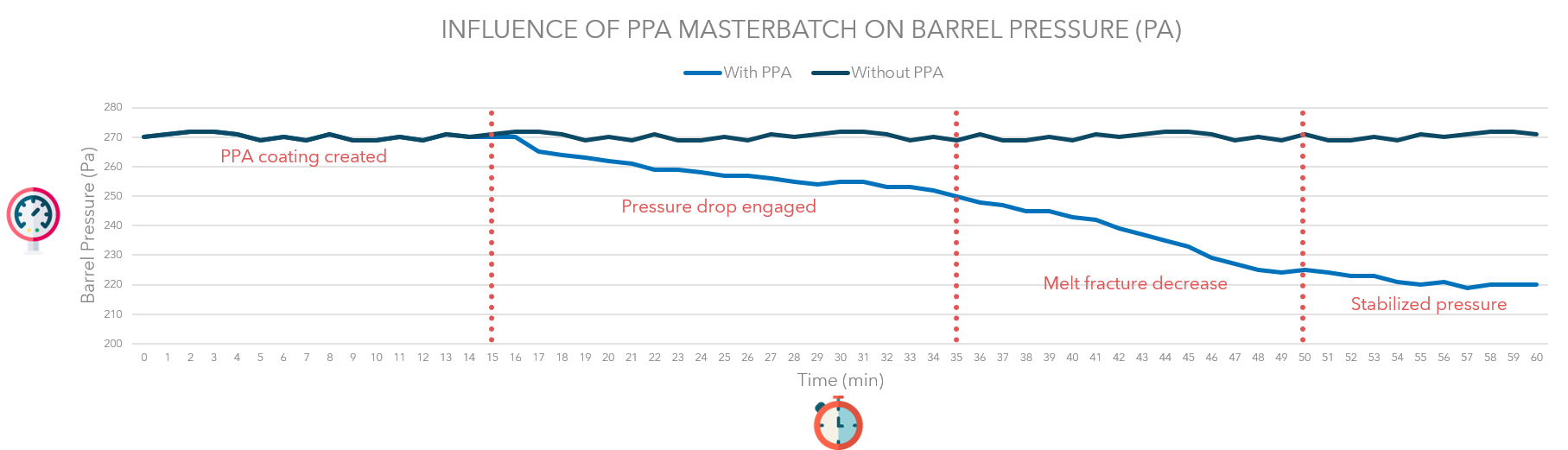

During 15/ 20 min, PPA masterbatch is sent at around 15% with the resin

inside the extruder/ barrel.

The additive presents affinity with metal structures It will then coat the barrel and the screw creating a protective layer.

After this time:

- Pressure Drop will be initiated

- Melt Fracture will happen at the middle of the drop

- Pressure will be then stablized

The masterbatch is still used in production at 1-1.5% to continuously regenerate the protective coating layer.

The grades

POLYMER PROCESSING AIDS

For polyethylene

- The standard grade: FX AID PE F5

GRADE

.

AID PE F5

APPLICATIONS

Blown films

Pipes & tubes

Polymer production & compounding

COMPATIBLE RESIN

.

LDPE

LLDPE

OPERATING T°

.

X < 240°C

- The premium grade: FX AID 10 614

GRADE

.

AID 10 614

APPLICATIONS

Blown films

Pipes & tubes

Polymer production & compounding

COMPATIBLE RESIN

.

LDPE

LLDPE

OPERATING T°

.

X < 240°C

- For high T° cast film: FX AID 10 650

GRADE

AID 10 650

APPLICATIONS

Cast films

COMPATIBLE RESIN

LDPE

LLDPE

OPERATING T°

X < 300°C

POLYMER PROCESSING AIDS

For polypropylene & TPV

- For BOPP / CPP & TPV: FX AID PP F4

GRADE

.

.

AID PP F4

APPLICATIONS

CPP & BOPP film conversion

PP Compounding

TPE-V Compounding

COMPATIBLE RESIN

.

PPh

PPc

TPV

OPERATING T°

.

.

X < 250°C