Slip & Antiblock Products Platform

An Antiblock masterbatch is usually added into a polymer film recipe to provide two main effects. The ease of rolling the polymer film on itself. During the process, air bubbles can be trapped in between film layers – causing defaults & non-flat film aspect during unwrapping. To avoid the blocking effect – caused by the adhesion between two layers.

Objective is to generate heterogeneous surface, brought by mineral or organic fillers. Polytechs SW Antiblock & Slip product range does provide industry standard references – and can provide tailor-made masterbatch upon request.

ANTIBLOCKS

3 TYPES OF PRODUCT NATURE

The grades

-

The grades with: NATURAL SILICA

Standard & Cost-effective Antiblocking filler with high quality consistency 15%, 30% & 50% filled

For Polyethylene

-

The grades with: SYNTHETIC SILICA

High COF reduction efficiency & High Transparency Loading level: 20% for PE & 10% for PP

For Polyethylene

For Polypropylene

-

The grades with: TALC

Talc with universal carrier – can be added in numerous polymer matrixes. Universal grade: 50% Talc-filled – PE: 30% Talc-filled

For Polyethylene

For EBA

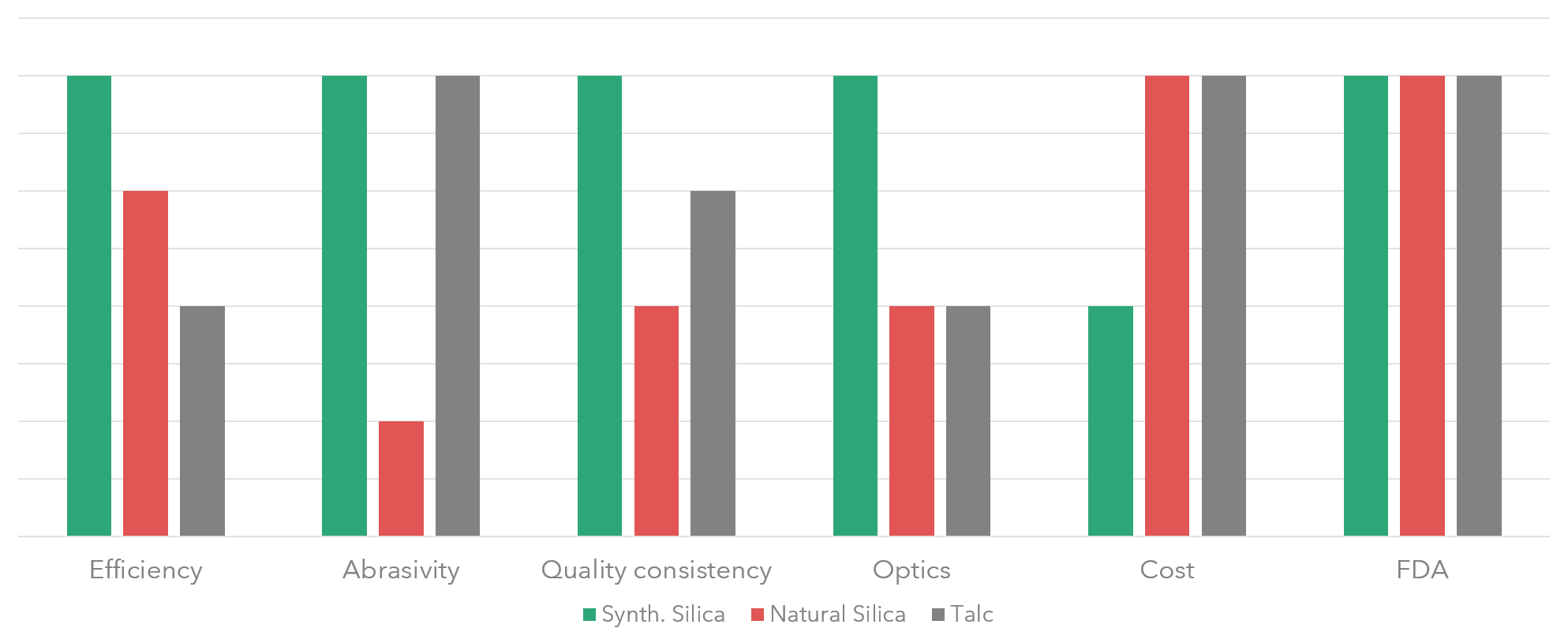

Comparisons of various antiblocks commonly used in the market

SLIP

ONE GRADE REFERENCE

-

The grade with: OLEAMIDE

SL PE OL 7.5

SL PE OL 7.5 is masterbatch of 7.5% active agent. This masterbatch reduces the coefficient of friction between polyethylene films with a faster migration time.